Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

When you decide to outsource fulfillment to a 3PL or another fulfillment service, one of the first things that you should get a grasp on, is their charges.

Fulfillment charges can be as simple as adding a flat fee to every item’s cost. Or, it can be a bewildering mess with multiple tiny charges that keep adding up. Enough to make your head spin, even if you are great with numbers.

Many ecommerce businesses fail to read the fine line when they sign up with a 3PL. They are surprised when the charges that were not so apparent at first, start to make an appearance later on, when they least expected.

That’s why we decided to create this handy guide to fulfillment costs and clear the smoke once and for all.

Fulfillment Costs are the charges that a 3PL or a fulfillment service charges to fulfill the order. It involves the costs for receiving inventory, storage in a warehouse, pick and pack, and shipping.

These processes may sound simple. But they involve complex processes, manpower, software and infrastructure, which a 3PL will pass on to you, the ecommerce business in the form of the fulfillment charge.

As an ecommerce business, it is crucial that you are well aware of the complete fulfillment cost well in advance, so that you can plan your profitability and ROI accordingly.

For instance, if you sign up for a 3PL expecting the fulfillment cost to be $2 per item and then later on, realize that there was a storage fee as well. Okay, so that eats up $0.50 from your profit. Wait, there’s a picking fee too. That’s another $0.25 gone. Uh oh! There’s unloading, which you forgot to account for.

Before you know, the unexpected costs have eaten into your profits reducing it to a trickle. To prevent that, here’s an overview of the general fulfillment charges that a business can expect when they sign up with a 3PL.

Let’s cut to the chase.

The entire fulfillment process can be broken down into 7-8 steps if you take a detailed look at it. But broadly speaking, there are four steps.

Setup, which is the initial onboarding process where the 3PL will integrate your store/inventory into their software and help you understand how it works. Many 3PLs throw in training as part of the onboarding process. Setup charges are mostly a one-time flat rate.

There’s receiving, which is the process for receiving your inventory at the warehouse and then logging it into their system. Receiving can be an hourly charge or a flat rate depending on the 3PL.

The next step is storage and warehousing. The inventory will then be stored in small bins, pallets, sorting it for effortless pick and pack. The charges may be based on the storage space, by square foot.

The last step is pick and pack, which is the process of picking the item from the warehouse, packing it and sending it for shipping.

There are hundreds of 3PL companies in the marketplace now and there can be as many pricing models to be honest. But we are going to keep things simple so that you can understand how to analyze a service.

Some 3PL companies have an all-inclusive charge for fulfillment. What does this mean, you wonder? It means that they consolidate all the different charges internally and give you one simple number to deal with.

Think of it like breaking down all the individual charges and then clubbing it together so that you don’t have to wreck your brains with each and every tiny charge.

The advantage of working with 3PLs that follow this pricing model is pretty obvious. You can easily calculate your procurement cost and hence, the profitability. There are no secret charges that will suddenly manifest in your monthly invoice.

You know from the onset what it’s going to cost you and how you can remain profitable even with this cost.

Some 3PLs have a complex pricing structure where they break down every individual charge. There’s a cost for receiving, unloading, loading into pallet, storage, time stored, pick, pack and shipping.

There can be additional charges as well, depending on the service you pick. As it would be obvious by now, a pricing structure like this will confuse you. It’s quite difficult to calculate your actual profit margins if unknown charges are going to keep popping out of nowhere.

Now that you have a fair idea of what to expect in terms of charges and pricing, let’s get down to the crux of the matter. What are the ballpark numbers that you can expect for these charges?

Here’s an overview.

Setup – Setup charges are another way to describe the initial onboarding fees that a 3PL will charge you. Some 3PLs have a flat fee for set up. This can range anywhere from $100 – 1500. Others offer a custom quote for setup charges depending on the type of inventory they are expected to fulfill and the volume.

The reason being, some inventory requires specialized storage solutions or compliance. These situations will be more resource-intensive for the 3PL and hence, will be charged higher. The Setup fee is generally charged one time only when you sign up with the company. Think of it like an upfront guarantee that you will not just onboard and then decide to switch to a different service provider.

Inbound Shipping & Receiving – The warehouse manager will receive the inventory, verify it, unload it, count it, sort it, enter it into their inventory management software and then store it, for pick and pack. This entire process is described as the receiving fee.

Depending on the service, this can be an hourly charge of say, $25-50 an hour. So, if it takes 6-man hours to unload and sort the inventory, it will cost you $300 to give you an overall idea. But it can be more or less.

Some services charge on a per item or per pallet basis. This can vary from $5-20 per pallet or more. If it’s charged per item, then it’s generally $0.10-0.25 per item.

Storage and warehousing – Storage and warehousing fees also vary based on the type of product, the amount of space it occupies, the duration of time that it is stored for, and whether or not, it requires any specialized storage containers.

Fulfillment centers may use one of these parameters to determine the charge or may use a combination of all of it. For example, ShipBob uses a fee structure based on the number of bins and pallets that your inventory occupies in the warehouse.

This is generally a cost-effective solution and the cost may range from $5-15 per pallet/month. But for some type of inventory, this may create dead space. Dead space is a term used to describe unused storage space that you end up paying for.

In such situations, a volumetric storage charge, such as the one charged by Deliverr may be a better choice. This generally ranges from $0.25 to $0.50 per cubic foot of storage space.

Pick & Pack – Pick and Pack is one of the most crucial steps in ecommerce fulfillment. It is something that can affect your fulfillment efficiency and hence, brand image.

A 3PL may have a separate charge for picking and packing, or may include it into their fulfillment fee. Shipmonk for instance, has a separate pick and pack fee which ranges from $1-$2.5 for the first pick and then $0.50 per additional item.

Deliverr on the other hand includes the cost for pick and pack in the fulfillment charge.

Shipping – Coming to another crucial determining factor, the shipping charge. Just because a 3PL has a network of warehouses in your target market does not mean that they offer cost effective shipping.

You must consider how they distribute inventory and what they charge you for shipping to the customer. For instance, ShipBob has 22 warehouses in the United States which they divide into shipping zones. There are Zones 1-10, based on where the inventory is stored.

For instance, let’s say you store inventory in their Chicago warehouse. You get an order from Missouri or Wisconsin, which are neighboring states to Illinois. You are charged a shipping rate for Zone 2, which will be cheap.

But as you keep moving away from Chicago, the zones change and the prices keep increasing. Most of Colorado for instance is Zone 5. But California is Zone 10.

ShipHero and Deliverr on the other hand, have a flat rate for shipping across the USA. That’s because they self-distribute the inventory to multiple warehouses in their network. This allows them to automatically ship inventory from a warehouse close to the customer’s destination. This is both, cost effective and fast.

Kitting and Returns – Kitting is a term used to describe product assembly, generally before fulfillment. But the same kitting charges also apply in case you want the 3PL to handle returns. It’s generally an hourly rate.

Not all 3PLs handle returns. The ones that do will charge a flat fee for inspecting the returned item for damages and restocking it into the warehouse or sending it for disposal. This can range from $1-$4 per item depending on the service.

Additional Charges – In addition to this, there may be administrative charges for work orders and account management charges that may be levied in the final invoice.

The rule of thumb is that the more bifurcated the fulfillment cost, the more cumbersome it is to figure out the actual procurement cost, and profitability.

The simpler the fulfillment charge breakup, the easier it is to figure out profitability. Based on the two pricing models that we shared above, we are going to help you calculate the fulfillment cost for your item.

The pick and pack fees will depend on the pricing model that the 3PL follows. To give you an example, Shipmonk uses a complex pricing system where the fulfillment charge is broken down into separate charges for each touchpoint.

If you are generating up to 500 sales a month, then Shipmonk will charge you $3 for the first item in every pick. If there’s more than one item in the order, then additional items will be billed at $0.75. This keeps reducing based on the volume you generate. For 500-1000 orders, the cost is $2.50 for the first pick and $0.50 for every item in the order.

For more than 1000 and less than 2500 orders its $2.25 for the first pick and $0.50 for others. There’s also a $0.20 charge on every item for inserting promotional material if any.

ShipHero on the other hand has a flat fulfillment charge based on the shipping method you choose. There are no separate charges for pick and pack, except when there are 4 more additional skus in an order.

A 3PL will calculate shipping fees based on the shipping zone, or based on actual weight or volumetric weight of the product. Some can use a combination of these two parameters to determine the charge.

For instance, ShipHero uses both these parameters to determine the shipping cost. They have three service levels. There’s the standard, the 2-day shipping and the overnight shipping. Zone 9 is for Puerto Ricco and some other outlying places.

If the item weighs 0.5 lbs. or less, the standard shipping charge is $5.6, 2-day is $11.69 and overnight is $35.54 in the US. The charges increase depending on the package weight.

ShipBob also uses a similar pricing pattern to determine shipping cost. If the item weight is less than 1 lbs. they use the item weight plus shipping zone (as described above) to determine the shipping cost. But when the item weight is over 1 lbs., they apply volumetric weight instead to determine shipping cost. So, they will use the dimensions and weight of the box that they use to pack the item in, and the shipping zone to determine the cost.

Once again, a 3PL may use a combination of the volumetric weight, the total duration of storage and other factors to determine the storage cost.

Deliverr for instance, uses a combination of dimensions, number of units, the time of the year (costs are higher during peak season) and the total storage time to determine the cost. They charge $0.025 per day per cubic feet from Jan to September. But the price increases to $0.080 per day per cubic feet during Oct to December, because this is when sales volumes are sky high.

If the inventory is stored for more than 365 days, then long term storage fees are applicable.

ShipBob on the other hand charges per unit and the number of days that it is stored for. It’s $5 per bin, $10 per shelf and $40 per pallet.

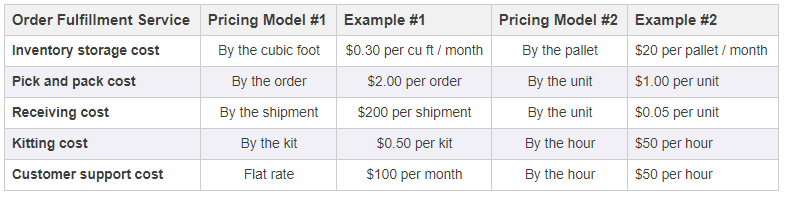

Below is a chart that overviews common order fulfillment fees and pricing models used by various 3PLs and ecommerce fulfillment companies:

The table above overviews common order fulfillment pricing models, although fulfillment providers will often have stipulations or add-ons related to these services.

For example, some fulfillment companies will charge a “long-term storage fee” if your merchandise sits in their warehouse for too long. So, while that company may advertise one storage rate, for many of your products, you may get hit with their long-term storage fee, which is substantially more costly.

Another example relates to minimums that are often imposed by order fulfillment centers. The company may advertise a low pick/pack rate, although that rate is predicated on doing a certain volume of orders each month, so if you don’t hit that volume, you are charged a minimum monthly fee, such as $500 or $1,000.

Because of the varying fulfillment pricing models out there, and because of these tricky fees that can be added on, it is important for merchants to get a firm handle on the total cost per order that they will pay based on their order volume, their products, and their requirements.

We spoke briefly at the onset about entrepreneurs being caught unaware with hidden fulfillment costs. What exactly are these? Let’s find out.

Let’s face it. Regardless of using the most cutting-edge software for workflow automation, there’s always a possibility that manual error might occur. Now, this can be manual error caused by you. For instance, the customer details are incorrect and you did not cross verify it.

In other situations, the error can be caused by the fulfillment center team. For instance, they did not verify the inventory and you ended up receiving more inventory than you ordered.

In either of these cases, some 3PLs will levy obscene charges to get these errors fixed. If you refuse to pay the charges, they will continue to bill you until you do.

Inventory storage in a fulfillment center is always expensive. There’s no two ways around this. That’s because fulfillment centers are not designed for long term storage. They are temporary solutions designed for quick inventory clearance and turn around times.

For instance, some 3PLs will charge you a storage fee according to a pallet or bin, whereas your product might be occupying only 10-20% of the pallet. Now if you do the math, you are paying for storage you are not using, every single day of the month.

On the other hand, services like Deliverr only charge a flat storage fee that’s not dependent on every unit, bin or pallet. So, unless you are clear about this up front, you might be in for a shock at the end of the month, when you realize how much money you are paying for storage alone.

In the event that you are unable to sell the inventory you ordered and there’s a lot of dead stock piling up, the 3PL will charge an additional fee to dispose the inventory.

With unsold inventory, chances are that you are already staring at a loss. Having to pay for inventory disposal adds insult to injury.

Fulfillment cost is one of the primary factors that affects your decision on which service to outsource to. We hope that this shines some light on an otherwise complicated parameter.

We have broken down the costs into individual ones to help you understand the ballparks, as well as spot unreasonable charges.