Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Amazon is the most popular e-commerce platform today. Who would have thought that the richest man in the world would be the CEO of the e-commerce platform? Amazon has become a way for millions of people to get rich, and many people want to try this business opportunity. Over the past two years, Amazon’s growth has been particularly dramatic.

We’ve supported more than 100 small business owners from the United States. They need our help to import from China and ship to Amazon’s FBA center.

Although they are new to the business, they do focus on designing their own packaging and adding their own brands to each branded product to implement the brand strategy.

There are so many articles on the Internet telling people about the advantages and solutions of private label, but no one shares their experience of “what to do” or “how much does it cost” or “what is the minimum quantity” of private label products imported from China. Maybe these people never really imported from China after all.

We help these new Amazon sellers add the private tags that best suit them according to their product category. In this blog we’ve looked at 14 of the most common solutions for adding tags/logos to products. You’ll learn a lot about how to add your own brand to your product and how much it will cost you.

A private label is a logo or design on a product. It represents the seller and helps promote brand awareness and build customer loyalty. If you want to start a business importing from China and selling on online marketplaces like Amazon, this is the simplest and best way to do it: find the quality product, find the best supplier for the product and buy it, then add a private label to the product and start selling the product under your brand name.

Private labels are the best way to differentiate your product from other products. Buyers are more likely to buy branded products, even if the two are identical.

Amazon is just as expensive as Alibaba’s products. And the brand will enhance the value of your products, you can sell your products at a higher price, your profit will be more considerable. Of course, the premise is that your brand positioning is high-end. The value of the product can be evaluated, but the brand is priceless.

For most categories of products, you can add a private label (your logo) to the body or packaging of the product. However, often the supplier will only tell you if they can add a private label to your product or packaging. You also have no idea that there are so many processes to add private labels, and their cost, process, time and MOQ are all different.

I have summarized the 14 major private label solutions that we have handled for our customers for a variety of products. Below we will go into detail about the pricing, MOQ, production time of these solutions, etc.

Screen printing refers to the logo through a special mesh to print ink on the substrate.

Screen printing is the most common and widely used method for adding your own logo to product bodies and packaging.

It can be applied to almost all products made of materials, such as plastic toys, glass bottles, stainless steel cups, rubber dumbbells and so on.

Silk screen printing has many advantages and is widely used in gift logo printing.

Advantages

Disadvantages

2. Not suitable for small batch order. A set of silk screen printing process cannot be saved. If the order volume is small, then these costs are quite high. Therefore, screen printing factories generally do not accept small orders because the cost is too high. This is also one of the reasons why many suppliers have higher MOQ for custom orders.

3. Not suitable for products with uneven surfaces

4. Some products must maintain their original state while printing, especially textile products. After printing, many customers want to maintain the texture of textiles, which is difficult to achieve with silk screen printing.

Charge standard

Screen printing is to see the size of the LOGO to calculate the price

Cost—- general 20-30 CNY. (If there is a ready-made film, this is not required)

Production time: 1 day

2. Mesh plate production

Cost: 60-80 CNY for a logo of 5*8CM.

Production time: 2-3 days.

3. Proofing —- divided into 2 situations: spot color and ordinary color

Ordinary color: 60-80 CNY

Spot color: 60-80 CNY+50 CNYcolor.

The total proofing cost is 160-180 CNY.

Proofing time: 5-7 days

4. Print LOGO

Cost: 0.2-0.5 CNY/logo within a size of 10CM length/3CM width (one color one position).

Smaller than A4 size: 1 CNY/logo (one color and one position)

A3 size: 2 CNY/color (one color, one position)

Take 5K order quantity, one color and one position as an example: it takes 3 days to print logo, 2 days for printing, 1 day for ink to dry. The total printing time is 6days.

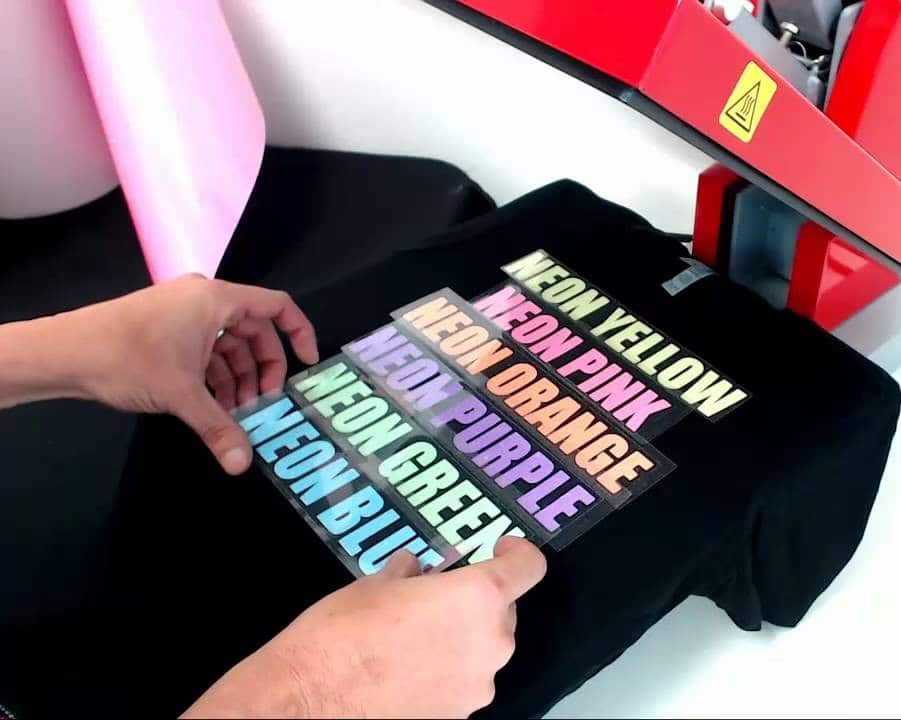

Thermal transfer printing is a more complex process than screen printing and requires a temperature range of 140°C to 180°C. As a result, it is a little more expensive than screen printing, and there are some limitations on materials. Applicable to ABS, PE, PP, EVA, leather, stainless steel, wood and glass. If you need to print fine patterns with a gradient, then the thermal transfer is your best choice.

Advantages

Disadvantages

Charge standard

Thermal transfer printing is divided into 2 technology, digital heat transfer and 2D/3D heat trandfer.

MOQ: 1000PCS/ pattern

The average price is 8-15 CNY/㎡

Delivery time: 7-12 days

2. 2D/3D heatl transfer printing ( take mobile phone case for example)

MOQ is less, usually 50PCS/pattern

The cost of different sizes of clamps is different, and the general clamps of mobile phone shell are 50-80 CNY.

Cooling mold: 120-150 CNY

Processing cost:

4.7 inches below: material 4.5 CNY, processing pattern 1.5 CNY

5.5 inches above: material 5.5 CNY, processing pattern 2 CNY

Delivery time: 5-10 days

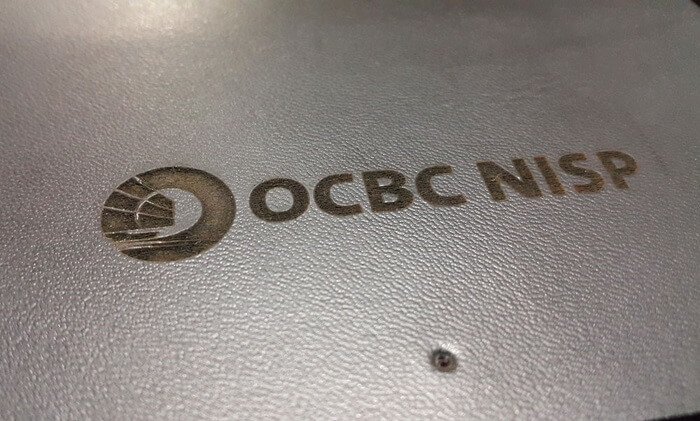

Laser engraving processing is based on numerical control technology, laser as the processing media. The physical denaturation of instantaneous melting and gasification of processed materials under laser engraving irradiation can make laser engraving achieve the purpose of processing. Laser engraving is the use of laser technology to write words on the object, this technology carved words without scratches, the surface of the object is still smooth, the writing does not wear. The printed logo pattern is realistic, the pattern is detailed, the level is clear, the three-dimensional sense is strong, mainly applies the high-grade gift precise pattern printing.

The process of laser engraving is as simple as printing on paper using a computer and printer; Can be in the Win98/Win2000/WinXP environment using a variety of graphics processing software, such as CorelDraw design, scanning graphics, vectorized graphics and a variety of CAD files can be easily “printed” to the engraving machine.

Advantages

1. The minimum order quantity is low because it does not require plate making. And the production speed is fast

2. Low cost: not limited by the number of processing, for small batch processing services, laser processing is cheaper

3. Safe and reliable: using non-contact processing, no mechanical extrusion or mechanical stress to the material. No “knife mark”, do not harm the surface of the workpiece.

Disadvantages

1. For metallic materials only, not for non-metallic materials

Charge standard

MOQ: Does not need to open the plate, the minimum order quantity is low, 50-100PCS.

Cost: 0.2 CNY/piece(logo size within 5CM)

Delivery time: Very fast, 5000-10000pcs only need 1 to 2 days to complete.

This means making a custom logo in the product mold, which means the logo will appear when the product comes out of the machine. The solution can be applied to any product made of plastic, rubber or metal.

Advantages

Disadvantages

Charge standard

The LOGO fixed on the mold. The cost of the mold of different materials and sizes is different. The cost of the mold of general plastic products is 15,000-20,000 CNY.

Activity inlay LOGO, mold cost 1000-3000 CNY

Production time: 15-20 days

Embroidery is mainly used for items made from cloth, such as clothing, hats and handbags. Compared to the logo printed on silk, it is more durable and looks more advanced, and this solution has no fading issues. However, it costs more than screen printing.

Advantages

Disadvantages

Charge standard

MOQ: 1000pcs

No plate fee, direct machine embroidery

Cost: 0.4CNY (within a size of 3*4cm, 1 color)

If the color is more than one, 0.1 CNY/color

Production time: only need 1 hour to produce 1000pcs

Woven label is a manufacturing process of finishing the logo pattern and color by weaving and embroidering on the processed fabric products with needles and threads in accordance with the logo design requirements.

Woven labels are usually sewn on the edges of items made of fabric, such as shoes, jeans, hats, and bags. Labels look better than printed logos. There are many traditional embroidery techniques, and color embroidery is usually used for gift logo embroidery.

This kind of embroidery technique has the characteristics of embroidered plain clothes, rich stitches, fine stitches and bright colors, and is most widely used in clothing and jewelry gifts.

Advantages

Disadvantages

Charge standard

Price components are: the width of the cloth label, the length of the cloth label and the length of each color along the warp direction.

MOQ: 2000 PCS/patten

Production cycle: 7-10 working days

Epoxy is a kind of two-component AB glue. The main components are epoxy resin, benzyl alcohol, polyether amine, with low viscosity, high transparency, yellowing resistance, good bending resistance and other characteristics.

After the signage and other printed parts are made, a layer of high tension coating is poured on the surface of the coating. The coating is raised to a height of 1.3mm, so that its appearance is camber.

Applicable to household appliances, TV, audio, MP3 / MP4, refrigerator, furniture, kitchen utensils, kitchen cabinets, bathroom, sanitary ware, plumbing, automobile and motorcycle accessories, mechanical equipment, electronic appliances, instruments, computers, communication equipment, refrigerators, air conditioners, washing machines, freezers, hardware home appliances, sports and leisure equipment, leather bags, business gifts and other industries.

Advantages

Disadvantages

Charge standard

MOQ: 500-1000PCS

Can be made in any size and shape, the specific quotation depends on the LOGO size, quantity, color, and printing requirements.

Cost:

Generally, for 4-color printed PVC Epoxy logo, if the size is within 3CM, the unit price of 1000pcs is about 0.3 CNY/pc

Proofing time: 5 days

Production time: 5-7 days.

Under the action of the mold, the thickness of the sheet material changes, and the process of pressing the undulating pattern or words on the surface of the parts is called embossing.

It uses the concave and convex die, under certain pressure, so that the printed matter plastic deformation, embossing a variety of convex graphics and patterns, showing different shades of patterns.

Embossed LOGO is generally used in packaging boxes, trademarks, calendars, leather, cloth above the most. There are two kinds of embossed LOGO, one is convex, the other is concave.

Advantages

1. Clear hierarchy

2. Three-dimensional image concentration

3. Accurate perspective Angle

Disadvantages

Charge standard

Embossed LOGO requires a copper mold/steel mold. Mold cost (depending on the size of the LOGO), the mold cost of a logo within 5CM is 600CNY

MOQ: 1000PCS

LOGO processing fee: 0.3CNY/LOGO within 5CM

Delivery time: 5 days

Offset printing is a kind of lithography, offset printing is the use of rubber (blanket) plate on the way of graphic print is passed on to the substrates. It is also called screen printing silica gel in the industry. Screen printing silica gel is a kind of special silica gel that can be firmly adhered to the surface of textiles, spinning cloth, imitation leather and other materials by screen printing.

Silk-screen silica gel is widely used for textile clothing signs, decorative patterns, sports gloves, anti-slip socks and handbags, travel bags, etc.

Advantages

Disadvantages

Charge standard

The cost of offset printing LOGO generally has 4 categories:

1. Screen cost: including screen frame, stretched plate and net cloth, etc.

2. Film cost: 100 CNY/㎡/color

3. Ink cost: general ink manufacturers will indicate how many square meters are printed per kilogram of ink, as well as thinners, etc.

4. Printing labor cost: Generally speaking, it is half-material and half-work, that is, 100CNY of the material cost will add 100CNY labor cost.

Amazon Suspends Amazon-Native Brands Mpow and Aukey over fake reviews

Stickers are definitely the simplest, cheapest and most widely used of all solutions. I really can’t think of anything that can’t be labeled. In the orders we have contacted, it is mainly used on the standard of cartons to mark the product or to mark some warning words.

Advantages

1. Needless to say, the biggest advantage of stickers is cheap. It’s the least expensive of all the options. But usually, you don’t go to the sticker supplier yourself. Your supplier will find a sticker factory, but they will not tell you the price is so low.

Disadvantages

1. Easy to drop. Self-adhesive stickers are not usually used alone, they are usually used in conjunction with plastic bags or cardboard or cartons.

Charge standard

MOQ: mold fee 80-120CNY (1000-3000 PCS, 3*4cm, 2 colors)

Meaning you only need to pay 120CNY for 3000 stickers. And then over 3,000pcs, 0.1/CNY.

Delivery time: 3-5 days

If your packaging budget is limited, and you don’t want to use too cheap plastic bags. You can consider using a cardboard custom logo. Print the logo and all other information on the cardboard, and then pack the goods in a cardboard box. Generally, retailers prefer to use cardboard for tool or kitchen product categories because it allows customers to easily see and touch products.

Advantages

Disadvantages

Charge standard

MOQ: 3000pcs

Cost: Affected by the type, size and quantity of paper

Start-up fee: minimum consumption of 600-800 CNY

For socks: 250g kraft paper

Blister cardboard: 0.3-0.5CNY/piece (250-300g white cardboard or coated paper, size 12*15cm)

Hangtag is a type of sticker that costs about the same as the sticker.

This is also a way to customize the logo. Compared with other packaging methods, printed plastic bags are simpler for bulk commodities. Usually applied to clothing, toys, tools, fashion accessories and other categories.

Advantages

Disadvantages

Charge standard

Different materials have different prices, which are mainly divided into OPP, PE and PVC materials, among which OPP is the cheapest

Mold fee: 260 CNY/ color

Behind MOQ: 10000pcs

Cost: 10000 PE bags, 0.2/ 20*15cm for face masks

Making your own design and printing it on a custom box works for almost any product.

Of course, this is the most expensive solution of the 11. An elegant packaging box can easily make your products look great. It’s also a way to add value and sell at a higher price!

Charge standard

MOQ: 3000piece

The cost calculation method of the color box:

Unit price = paper cost + pit cost + film fee + PS plate fee + printing fee + surface treatment fee + rolling work + mounting work + knife mold + paste work +1.5% loss + profit

1. Film fee: 0.3 CNY/color/square inch

2. Paper price:

Paper specifications: standard gauge 78.7 X 109 CM and large gauge 89 X 119 CM

Gray copper 4000CNY/T (futures) 4500 CNY /T (spot)

Single copper 7000 CNY/T (futures) 8600 CNY /T (spot)

Double copper 6500 CNY/T (futures) 8000 CNY /T (spot)

3. PS fee:

A. Small version 100 CNY/sheet

B. Large version 125CNY/ sheet

4. Printing fee (with 1000 sheets as the pricing unit):

The small version is calculated as follows (the large version is 1.25 times the small version

Below 1K 130 CNY /color (maximum)

1K-4.9K 100 CNY /color

5K-9.9K 75 CNY /color

10K-19.9K 55 CNY /color

Above 20K 50 CNY /color (minimum)

Pay attention to the following points:

1). The ordinary spot color is calculated as 1.5 times the ordinary color, (unit price*1.5)

2). Normal gold is calculated as 2 times normal color (unit price*2)

Generally, the cost of a color box requires an additional plate-making fee and a charge for die-cutting tooling. Normal size projection plate costs 300-600CNY, charge for die-cutting tooling is 150 CNY.

The general standard printing is 0.1 CNY/color, and the laminated is 0.6-0.8 CNY/㎡